I have an ongoing project that requires the drilling and threading (tapping) of aluminium on it's end. After laboriously performing several of these by hand I thought; 'there must be a better way, I wish my CNC could do this'. After considering this for some time I had realised that; if I feed the stock up through the bottom of my CNC and clamp it securely, I should be able to mill into the end of the stock which would be much faster and indeed more accurate than doing the same by hand. The modification to the CNC was then, the challenge for this weekend.

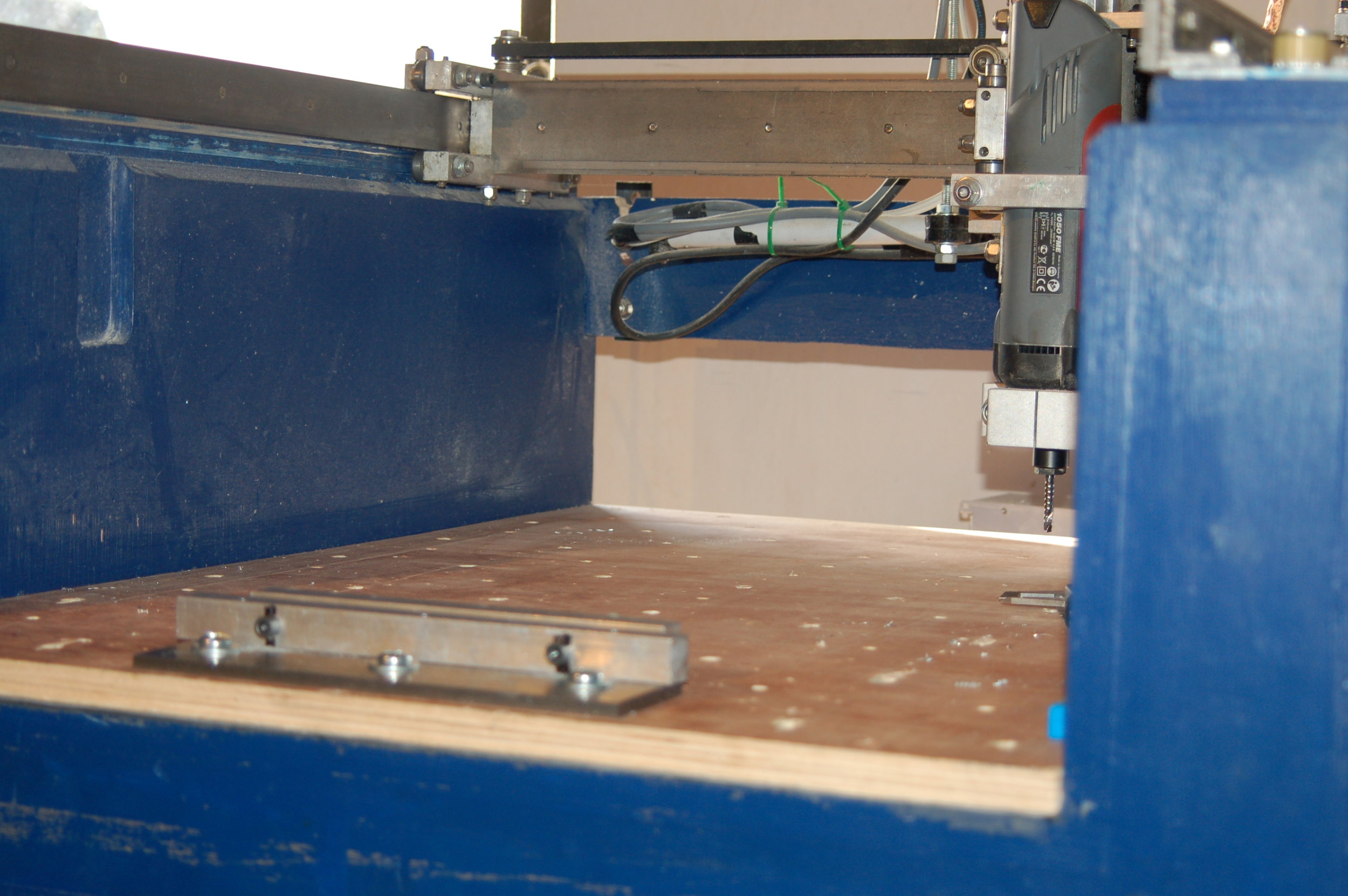

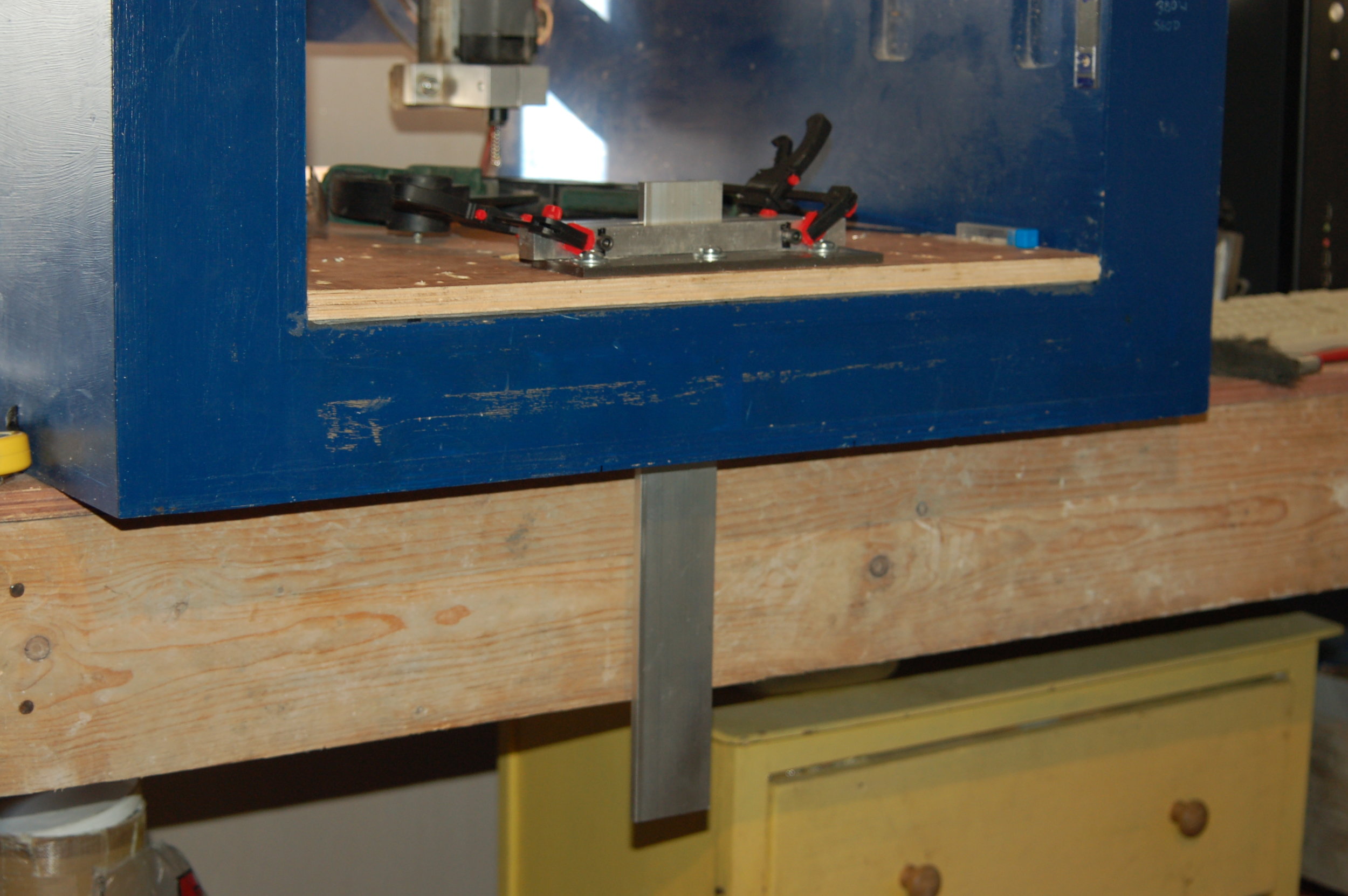

I began by using the CNC itself to cut a hole through the front end of the CNC base. This ensures that the hole is 'square' with reference to the tool. By using the longest tool available to me I was able to obtain a clean, square cut through the sacrificial layer (top layer of plywood), through the epoxy levelled surface underneath, and also through the lower layer of plywood. Moving the CNC forwards on my bench, such that it was overhanging slightly, allowed me to access the base from underneath. Some drilling, chiseling and Jigsaw work later; and we have a fairly nice oblong hole through the entire base of the CNC.

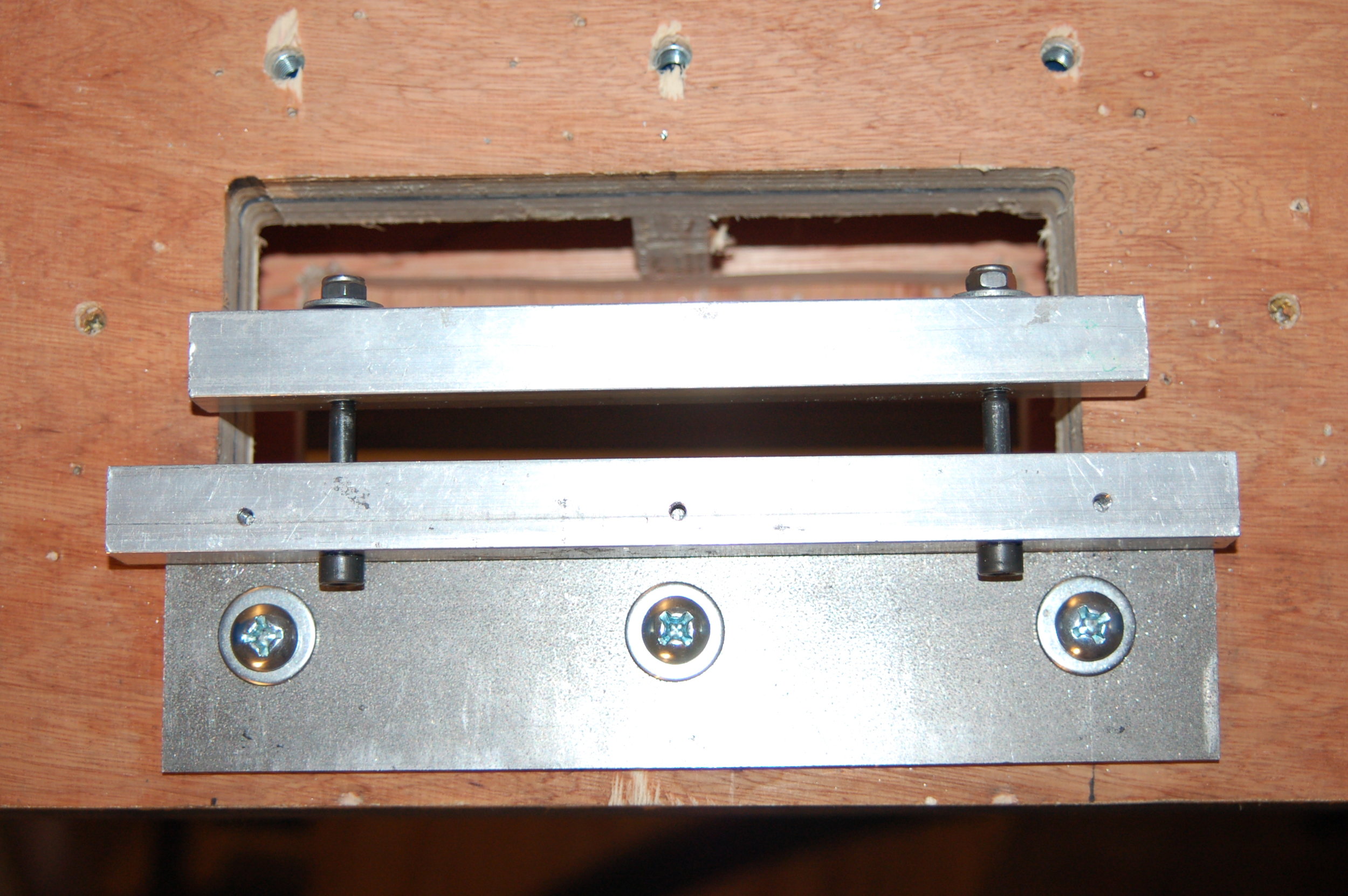

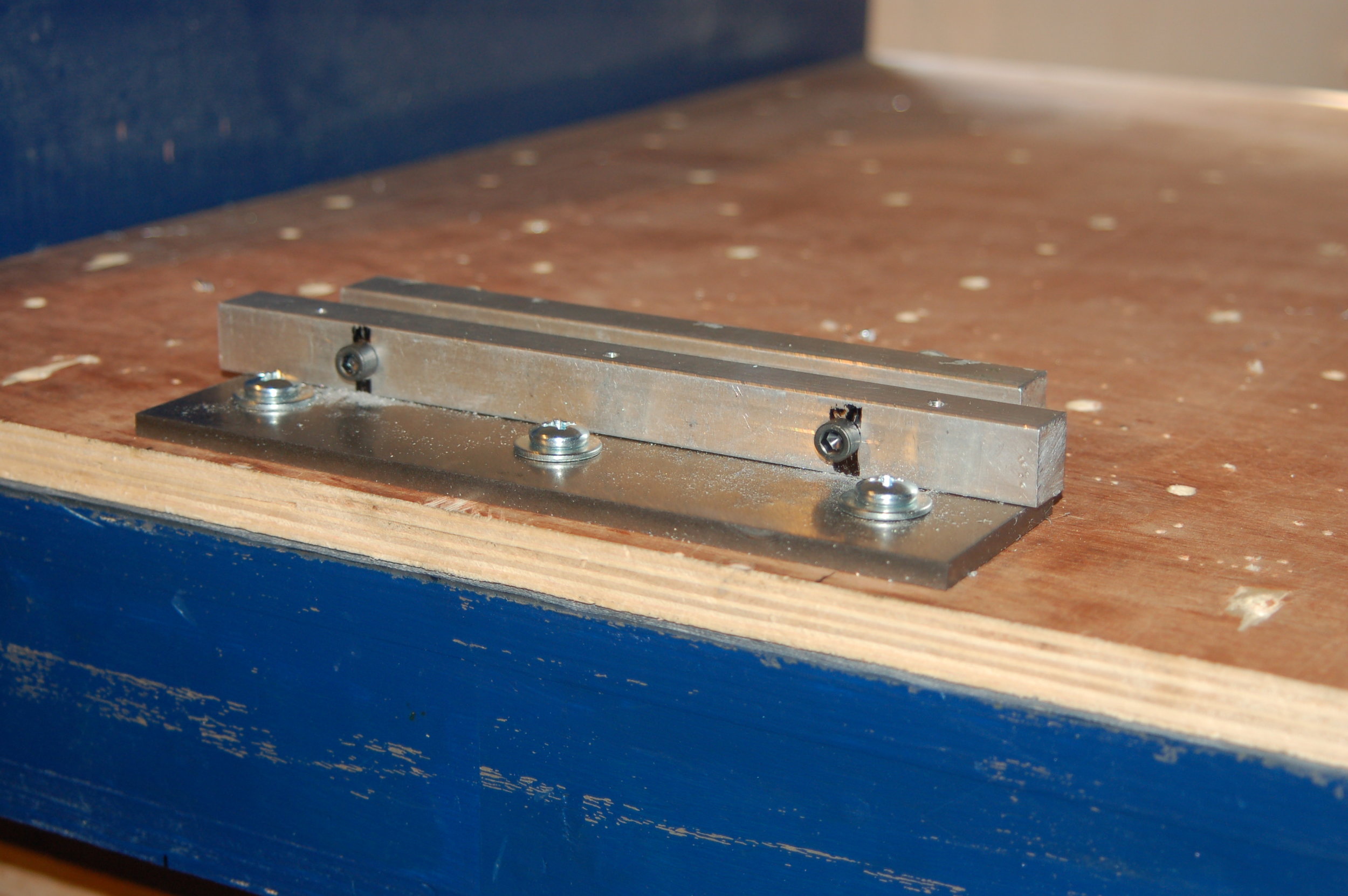

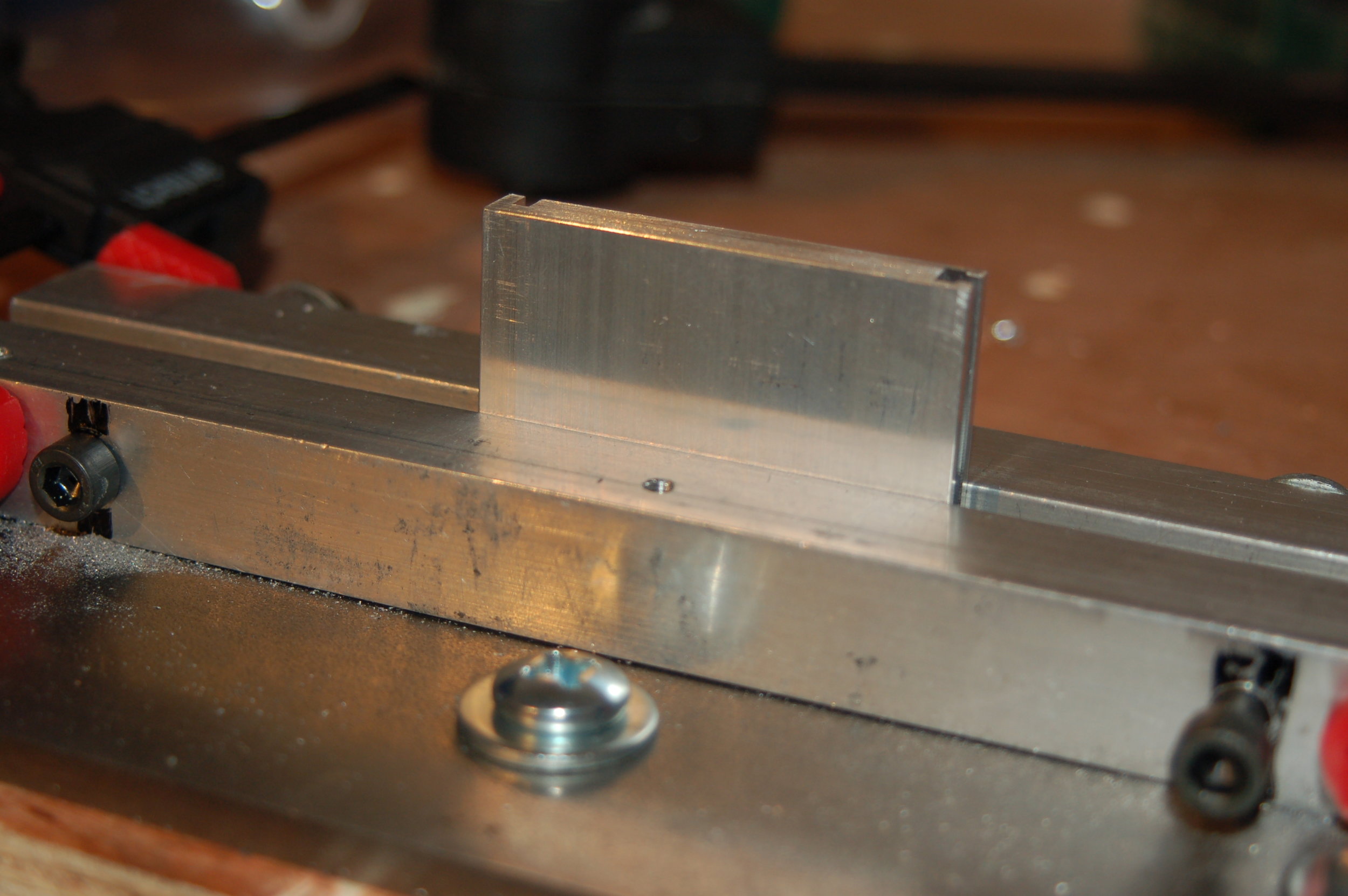

Using some scrap materials I then constructed a low profile clamping mechanism that uses M6 bolts to clamp two pieces of aluminium bar stock together in order to secure the workpiece. A piece of cold-rolled steel is used as a strong base and is used to bolt the 'vice' to the machine bed. M8 bolts pass through this steel flat section and allows for easy attachment/removal. Clamping of material in this 'vice' will be a fairly slow process, however, it will certainly be faster than drilling all of this stock by hand.

Time allowing I may add some guides to help with vertical alignment of the stock. I'm still considering the best way to approach that however.